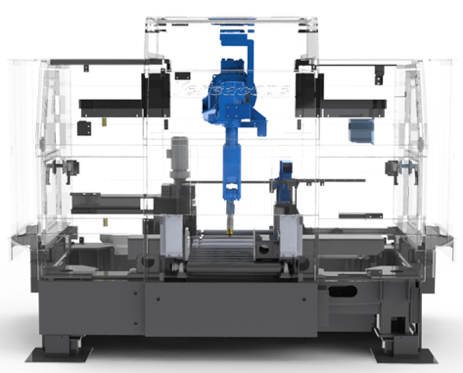

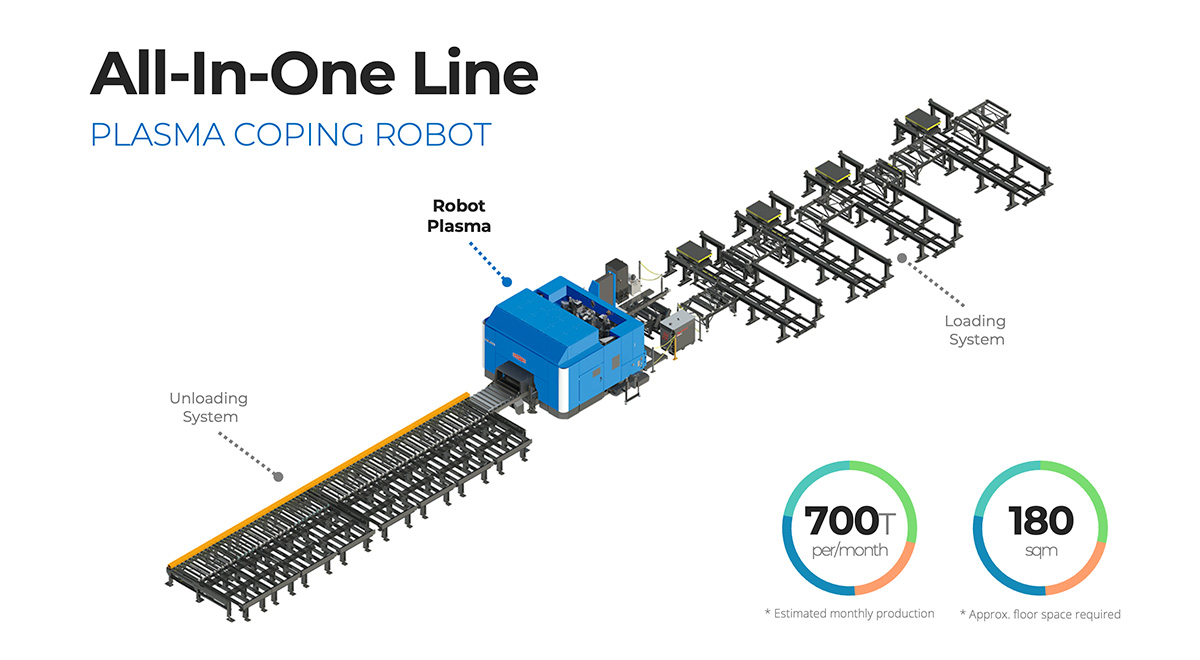

DAITO CR SERIES

CNC BEAM PLASMA COPING ROBOTS

YASKAWA MOTOMAN HIGH SPEED ROBOT

New Yaskawa Motoman Robot Features

* High-precision drives

* Higher accuracy.

* Compact design.

* Advanced collision avoidance.

* Reduced vibration at the torch.

* Ultra-fast processors and software.

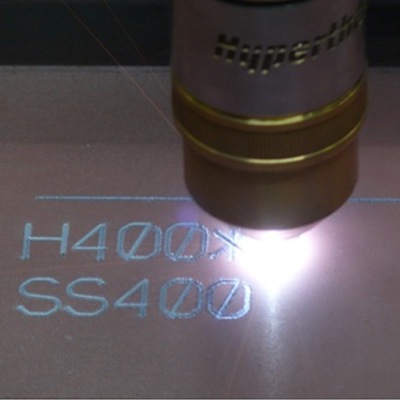

XPR300™ HYPERTHERM® HYPERFORMANCE PLASMA

The new XPR300™ represents the most significant advance in plasma cutting technology, ever.

* X-Definition™ cut quality.

* Increased cut speed.

* Dramatically improved productivity.

* Lower operating costs.

* Piercing up to 50mm (with argon assist).

* Edge-start up to 80mm.

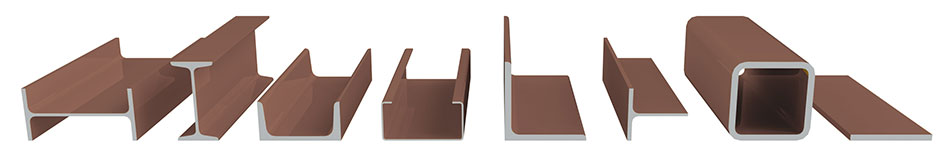

Vartiety of Processing

BOX TUBING

ANGLE CUTTING

dog bone cutting

advanced feeding system

HYBRID FEED SYSTEM

SHORT PARTS Handling